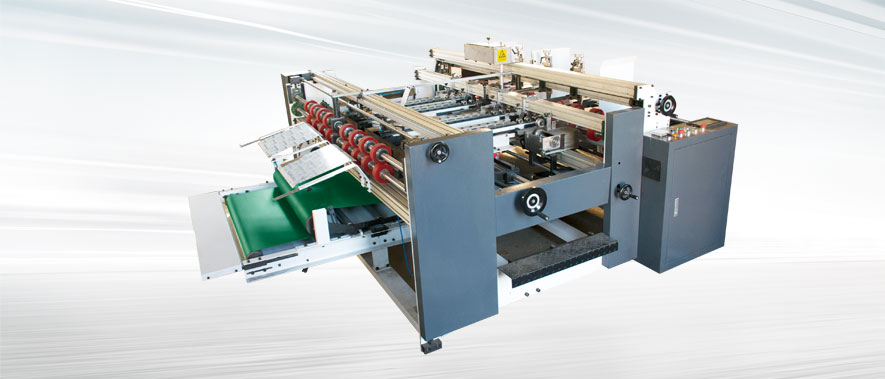

AB Pieces Folder Gluer is my company to solve customers about double sheet forming products and developed a targeted new products, can realize the monolithic molding with double sheet forming control.

To the part of the paper use suction paper feeding mode, makes an exact double feed distance; coating part adopts hotmelts heating system, sticky mouth, fast bonding; the cold glue system, facilitate bonding of artificial correction, the maximum will scrap rate reduced to a minimum; paper pressing part through the baffle plate and the photoelectric switch with the carton first bonding is accurate.

The main parts of the whole machine is made of domestic well-known manufacturers of original products, long service life, good stability, the electrical part adopts the world famous brand, key parts imported bearings, ensure the stable performance of the machine.

HXJ2000 Specifications

| Model | HXJ2000 |

| Max. paper size | 1000x720mm |

| Mini. paper size | 450x320mm |

| Machine speed | 120米/分 |

| Overall Dimension | 3450x3150x1180mm |

| Machine Power | 5.8Kw |

| About Weight of Machine | 3.5T |

Feeding part

The punch belt inlet, suction paper feeding mechanism, strong suction, feeding a smooth.

Paper-transfering part

The original design of the mechanism, adopts a steel ball with belt feeding, causes to lose the paper accurately, has good ability to adapt to the flat box mouth and irregular box.

Gluing part

The first time the hot melt adhesive, uniform coating, accurate positioning, firm adhesion. The second adhesive with cold glue, glue evenly, easy artificial correction.

Electric part

All electrical appliances all adopt the world famous brand, stable and durable, variable speed, low noise, energy saving.